Our Product line

Spur Gear

Gears having cylindrical pitch surfaces are called cylindrical gears. Spur gears belong to the parallel shaft gear group and are cylindrical gears with a tooth line which is straight and parallel to the shaft.

Spur gears are the most widely used gears that can achieve high accuracy with relatively easy production processes. They have the characteristic of having no load in the axial direction (thrust load). The larger of the meshing pair is called the gear and smaller is called the pinion.

Helical Gear

Helical gears are used with parallel shafts similar to spur gears and are cylindrical gears with winding tooth lines. They have better teeth meshing than spur gears and have superior quietness and can transmit higher loads, making them suitable for high speed applications. When using helical gears, they create thrust force in the axial direction, necessitating the use of thrust bearings. Helical gears come with right hand and left hand twist requiring opposite hand gears for a meshing pair.

Gear Rack

Same sized and shaped teeth cut at equal distances along a flat surface or a straight rod is called a gear rack.A gear rack is a cylindrical gear with the radius of the pitch cylinder being infinite. By meshing with a cylindrical gear pinion, it converts rotational motion into linear motion.

Gear racks can be broadly divided into straight tooth racks and helical tooth racks, but both have straight tooth lines. By machining the ends of gear racks, it is possible to connect gear racks end to end.

Bevel Gear

Bevel gears have a cone shaped appearance and are used to transmit force between two shafts which intersect at one point (intersecting shafts).

A bevel gear has a cone as its pitch surface and its teeth are cut along the cone.

Kinds of bevel gears include straight bevel gears, helical bevel gears, spiral bevel gears, miter gears, angular bevel gears, crown gears, zerol bevel gears and hypoid gears.

Screw Gear

Screw gears are a pair of same hand helical gears with the twist angle of 45° on non-parallel, non-intersecting shafts. Because the tooth contact is a point, their load carrying capacity is low and they are not suitable for large power transmission.

Since power is transmitted by the sliding of the tooth surfaces, it is necessary to pay attention to lubrication when using screw gears. There are no restrictions as far as the combinations of number of teeth.

Miter Gear

Miter gears are bevel gears with a speed ratio of 1. They are used to change the direction of power transmission without changing speed. There are straight miter and spiral miter gears.

When using the spiral miter gears it becomes necessary to consider using thrust bearings since they produce thrust force in the axial direction. Besides the usual miter gears with 90° shaft angles, miter gears with any other shaft angles are called angular miter gears.

Worm Gear

A screw shape cut on a shaft is the worm, the mating gear is the worm wheel, and together on non-intersecting shafts is called a worm gear. Worms and worm wheels are not limited to cylindrical shapes. There is the hour-glass type which can increase the contact ratio, but production becomes more difficult. Due to the sliding contact of the gear surfaces, it is necessary to reduce friction. For this reason, generally a hard material is used for the worm, and a soft material is used for worm wheel.

Spiral Bevel Gear

Spiral bevel gears are bevel gears with curved tooth lines. Due to higher tooth contact ratio, they are superior to straight bevel gears in efficiency, strength, vibration and noise.

On the other hand, they are more difficult to produce. Also, because the teeth are curved, they cause thrust forces in the axial direction.

Within the spiral bevel gears, the one with the zero twisting angle is called zerol bevel gear.

Internal Gear

Internal gears have teeth cut on the inside of cylinders or cones and are paired with external gears. The main use of internal gears are for planetary gear drives and gear type shaft couplings. There are limitations in the number of teeth differences between internal and external gears due to involute interference, trochoid interference and trimming problems. The rotational directions of the internal and external gears in mesh are the same while they are opposite when two external gears are in mesh.

Herringbone Gear

GA herringbone gear, a specific type of double helical gear, is a special type of gear that is a side to side (not face to face) combination of two helical gears of opposite hands.

From the top, each helical groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the bones of a fish such as a herring). Unlike helical gears, herringbone gears do not produce an additional axial load.

Anti Backlash Gear

Anti-Backlash Gears are gears having minimum or no backlash (play).Anti-backlash capabilities can be applied to many types of gears, and is most commonly seen in spur gears, bevel gears, miter gears, and worm gears.Sometimes backlash is a favorable and necessary part of the way gears work, but in some situations it is desirable to have little or no backlash.Backlash, sometimes called lash or play, is a clearance or lost motion in a mechanism caused by gaps between the parts.

Grounded Anti Backlash Gear

Backlash is a necessary function for gearing, however anti-backlash spur gear can remove backlash mechanically.The principle KG-Anti backlash spur gear is that of a time-honored method, KG-Anti backlash spur gear has springs that produce load. These springs generate larger torque than the axial torque applied to a pairof gearbox. Select Allowable torque based on calculation of load produced from the springs

Grounded Controled Backlash Gear

Precision ground gears are manufactured by using abrasive wheels to grind a gear blank to match the desired gear design.

These versatile gears are better suited to use with fine instrumentation and other small-scale components, and in high precision applications.

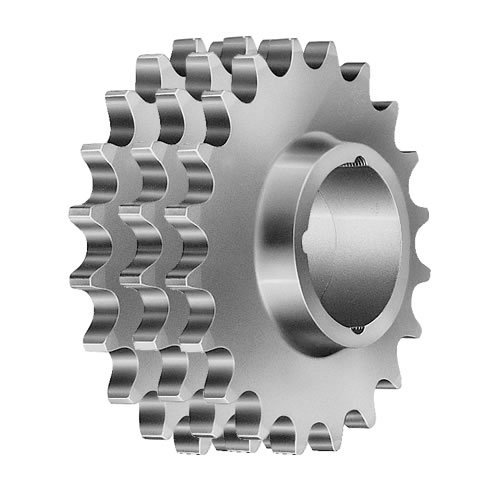

Sprockets Gears

A sprocket or sprocket-wheel is a profiled wheel with teeth, or cogs,that mesh with a chain, track or other perforated or indented material.The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passing over it. It is distinguished from a gear in that sprockets are never meshed together directly, and differs from a pulley in that sprockets have teeth and pulleys are smooth.

Circular Pitch Pinion Gear

The diametral pitch of a gear is the number of teeth per inch of pitch diameter. Pitch diameter is the pitch circle below.

It specifies the tooth spacing along the pitch circle of each gear, which must be the same for the gears to work together.

It's used to know that two gears will mesh.

Worm Wheel Gears

Backlash is a necessary function for gearing, however anti-backlash spur gear can remove backlash mechanically.The principle KG-Anti backlash spur gear is that of a time-honored method, KG-Anti backlash spur gear has springs that produce load. These springs generate larger torque than the axial torque applied to a pairof gearbox. Select Allowable torque based on calculation of load produced from the springs

Gears Box Types

| Type | Description | |

|---|---|---|

| HY | Hypoid gear box | Right angle |

| BS | Bevel gear Box | L Type |

| BSH | Bigger bevel gear box | T type |

| BE | Bevel gear set | |

| WS | Worm gear box |

Gears

| Gears Type | Description |

|---|---|

| NS | Anti backlash gear |

| NSG | Grounded Anti backlash |

| ASG | Grounded controled backlash |

| S | Spur gear |

| SG | Grounded Spur gear |

| SGE | Grounded Spur gear |

| IS | Internal gear |

| RKG | Graunded Rack |

| RKGP | Graunded Circular Pitch Rack |

| SGP | Circular Pitch pinion |

| H | Helical gears |

| W | Worm gear |

| G | Worm wheel |

| M | Spiral/Miter gear |

| B | Bevel gear |

| SW | Sprokets |

Gears Materials

| Materials | Description | |

|---|---|---|

| AL | Aluminium | Aluminium |

| S | S45C Carbon Steel/mild | S45C |

| ASG | Chromium Molibednum | Chromium Molibednum |

| S | SCM435Cro-Mo, 440SS with HC | SCM435, 440 |

| SU | SCM435, 440 Chromium Molibednum | SUS304 |

| SG | SCM435, 440 Chromium Molibednum | SCM435, 440 Chromium Molibednum |

| SGE | S45C Carbon steel/ mild | S45C |

| B | Brass | |

| DM | Poli Acetal | |

| DB | Poliacetal with brass bushing |